-

조나트하스그들이 제안한 연결기는 오래된 것들을 대체하도록 사실상 적당합니다. 가격은 스헴을 받기 위해 앞으로 합리적이고 보입니다.

조나트하스그들이 제안한 연결기는 오래된 것들을 대체하도록 사실상 적당합니다. 가격은 스헴을 받기 위해 앞으로 합리적이고 보입니다. -

호세내가 모두 정확하게 한 DF8B 예비품. 생산 소요 시간은 빠르고 언제든지 나 햇빛이 찬란한 문제가 있고 나를 돕기 위해 여기에서 항상 있습니다. 상당히 그녀에게 감사하고,와 다시 우리의 미래의 협력을 기대합니다.

호세내가 모두 정확하게 한 DF8B 예비품. 생산 소요 시간은 빠르고 언제든지 나 햇빛이 찬란한 문제가 있고 나를 돕기 위해 여기에서 항상 있습니다. 상당히 그녀에게 감사하고,와 다시 우리의 미래의 협력을 기대합니다.

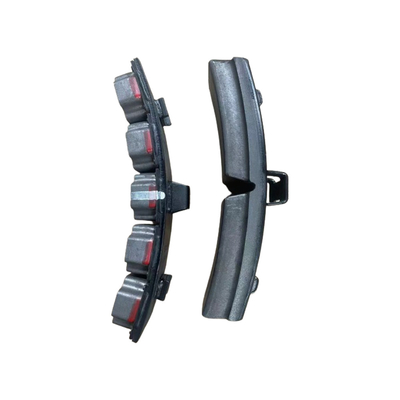

High Performance UIC Railway Brake System Powder Metallurgical Brake Shoe

| 제품 이름 | 철도 브레이크 블록 | 소재 | 분말 야금학 |

|---|---|---|---|

| 적용 | 철도 왜건, 승용차 요법. | MOQ | 1000pcs |

| 점검 | 국내 또는 지정 | 서비스 | 맞춤형 서비스 |

| 속도 | 80-120km/시간에 사용 | 특징 | 친절하게 환경적입니다 |

| 장점 | 팽창 강도 | ||

| 강조하다 | 고성능 철도 제동 시스템,UIC 철도 제동 시스템,파우더 금속 철도 브레이크 시스템 |

||

Product Overview

When the train is running and braking, the brake part that directly rubs the wheel to stop the train is the brake shoe; the

tile-shaped brake block made of cast iron, composite material or other materials holds the wheel tread tightly and makes the wheel stops rotating through friction.

Powder metallurgy materials are made by taking metal powder as a matrix, properly adding friction agent, lubricant and other components, and pressing and controlling high-temperature sintering (900-1050 ºC).

According to the requirements of braking friction performance, powder metallurgy brake shoes are divided into low friction

coefficient brake shoes, standard friction coefficient brake shoes, and high friction coefficient brake shoes.

The brake shoe is composed of a shoe back, steel back, and friction body.The brake shoe back shall be made of steel plate with mechanical properties not lower than Q235.The friction body is made of metal or its alloy as the matrix, added with other metal and non-metal components for friction,friction reduction or some special functions, and sintered with the steel back by powder metallurgy technology.

The brake shoe shall be free of asbestos, lead or its compounds, and other materials that may endanger human health and may produce harmful gases, dust or compounds.

The locomotive powder metallurgy brake shoe has the advantages of high and stable friction coefficient, wear resistance, excellent thermal conductivity, good thermal cracking resistance, and stable friction coefficient in rainy and snowy weather.

![]()

Product Specification

| Product Name | Railway Brake Blocks |

| Material | Powder metallurgy |

| Braking Force | 1. High friction(2.8~3.2) 2. Low friction(1.7~2.2) |

| Density(g/cm3) | Not more than ± 5% |

| Speed | <160km/h,160-200km/h |

| Application | Railway wagon, passenger car ect. |

| Hardness(HBW10/1000) | ≤120 |

| Compressive strength(MPa) | ≥90 |

Advantage

- Customized according to customer requirements

- Friction property can be adjust according to requirement.

- Good wear resistance and long life span.

- Its no Crocidolite in Ironstone(asbestos).

- It contains no lead, zinc or any other toxic materials,

- it is environmental friendly, and causes no bad smell in friction.

Application

Specific products include:

· Wheel set: axle, wheel

· Bearing & axle box

· Spring & vibration control system: steel spring, rubber spring, air spring, leveling valve, shock absorber and other truck components

· Coupler & draft gear device

· Braking system that meet UIC & AAR requirements

· Passenger train facilities & equipment: window, handrail, luggage rack, seat, HVAC system, toilet, gangway, plug door, interior products

· Locomotive parts

![]()